Best Real Bearing Types for Your Needs?

When selecting the best Real Bearing types for your application, the choices can be overwhelming. Industry expert Dr. Emily Carter once stated, "Understanding your specific needs is key to choosing the right Real Bearing." This highlights the crucial nature of informed decision-making in bearing selection.

Real Bearings come in various styles and materials, making them suitable for diverse applications. There are deep groove ball bearings, tapered roller bearings, and even ceramic options. Each type has distinct advantages, but the choice is not always clear cut. Sometimes, clients prioritize cost over quality, which can lead to future performance issues.

It's essential to reflect on your requirements. What machinery will the Real Bearing be used in? What loads will it bear? Sometimes, the best choice isn't the most obvious one. Investing time in research can prevent costly mistakes later on. Understanding these aspects is critical for optimal performance and longevity in your operations.

Understanding the Different Types of Bearings and Their Applications

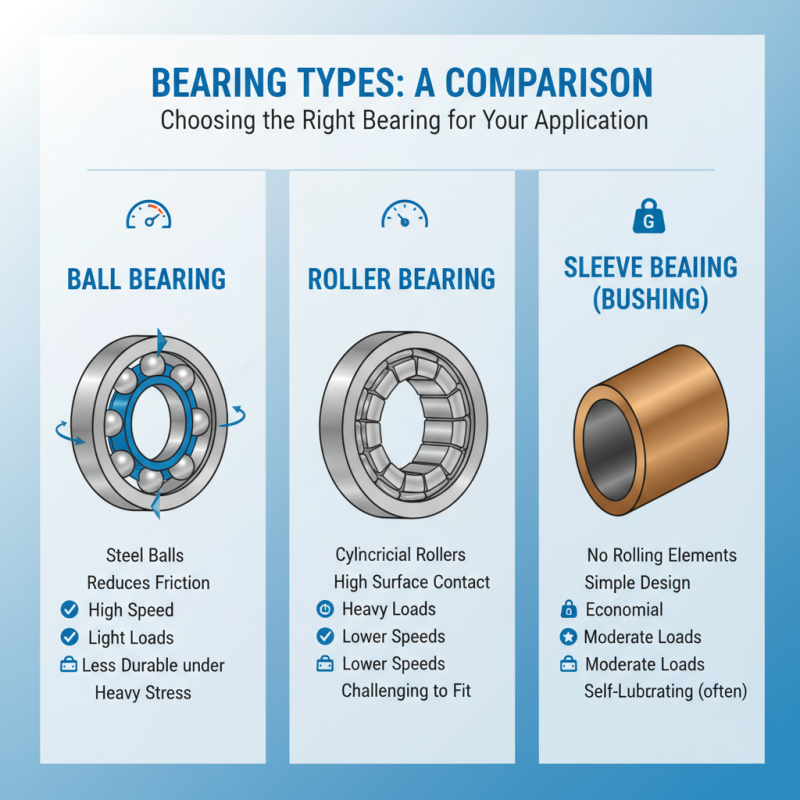

When choosing the right bearings, understanding their types is crucial. There are several common bearing types, each serving different purposes. For example, ball bearings are popular for their versatility. They can handle both radial and axial loads. Roller bearings, on the other hand, excel in heavy loads with a greater surface area. Each type has its strengths and weaknesses.

The selection process can be overwhelming. Sometimes, people overlook specific needs. For high-speed applications, one must consider ceramic bearings. They offer lower friction compared to steel. However, they may not be as durable under certain conditions. Nylon bearings work well in lightweight applications but lack strength under heavy loads. It's vital to reflect on the operating environment and intended load.

Bearings can affect machinery efficiency significantly. Misjudging the type can lead to failures. Not every application demands the highest-grade bearings. Sometimes, cost-effectiveness needs more attention. Each choice carries trade-offs. Evaluating priorities will yield better outcomes.

Key Factors to Consider When Choosing the Best Bearing for Your Needs

Choosing the right bearing is crucial for various applications. Key factors include load capacity, speed, and durability. Load capacity determines how much weight a bearing can sustain. Data shows that exceeding this limit can lead to rapid wear. In fact, nearly 30% of bearing failures stem from incorrect load conditions.

Speed is another vital aspect. Bearings designed for high speeds need specific materials and structures. The right choice can enhance performance, increasing equipment efficiency by up to 20% when compared to standard options. However, many users overlook this detail, leading to suboptimal results.

Lastly, consider the operating environment. Factors like temperature, moisture, and contamination affect bearing life. According to a reliability report, 40% of bearings fail due to environmental factors. This emphasizes the need for proper sealing and lubrication. Users should assess their conditions carefully. Ignoring these factors can lead to expensive downtime and repairs. Inconsistent maintenance practices can also result in premature failure, which is often underestimated.

Comparative Analysis of Ball Bearings, Roller Bearings, and Sleeve Bearings

When selecting bearings, it's essential to understand the differences between ball bearings, roller bearings, and sleeve bearings. Ball bearings have steel balls that reduce friction and are well-suited for high-speed applications. They perform best in light loads but may wear out faster under heavy stress. Roller bearings, on the other hand, contain cylindrical rollers, making them ideal for heavier loads. They offer increased surface area contact, which reduces stress, but they can be more challenging to fit into tight spaces. Sleeve bearings, or bushings, provide a simpler design without rolling elements. They are often more economical and work well in moderate load conditions.

Tips: Consider the load requirements when choosing bearings. Think about your space constraints, as roller bearings can often be bulky. Ensure you account for both the speed and environmental factors like temperature and lubrication.

Choosing the right type of bearing may feel overwhelming. It is important to evaluate how each option aligns with your specific needs. A common mistake is focusing solely on one characteristic, like load-bearing capacity. Don't forget to consider the operating environment too. Improper choices could lead to premature failure or excessive maintenance. Aim for balance in performance, cost, and longevity in your selection process.

Industry Innovations: Recent Advances in Bearing Technology and Materials

Recent advances in bearing technology and materials are reshaping industries. New designs focus on efficiency and durability. One major innovation is the use of advanced polymers. These materials offer significant weight reductions without sacrificing strength. The result is better performance in demanding applications.

Another exciting development is the integration of smart technology into bearings. Sensors embedded in the bearings collect data on performance and wear. This information helps predict failures and optimize maintenance schedules. Companies are increasingly turning to these smart solutions. However, the integration process can be complex. Some industries may find it challenging to adopt these technologies fully.

As innovative materials emerge, the importance of sustainability grows. Eco-friendly options, such as biodegradable lubricants, are gaining traction. Manufacturers are also exploring recycling methods for old bearings. These efforts highlight a shift towards greener practices. Yet, not all solutions are perfect. Balancing performance, cost, and environmental impact remains a critical challenge. The journey to find the best bearing types continues, with room for exploration and refinement.

Best Real Bearing Types for Your Needs

This chart illustrates the popularity ratings of various types of bearings based on recent industry insights and innovations in technology and materials.

Maintenance Practices to Extend Bearing Life and Improve Performance

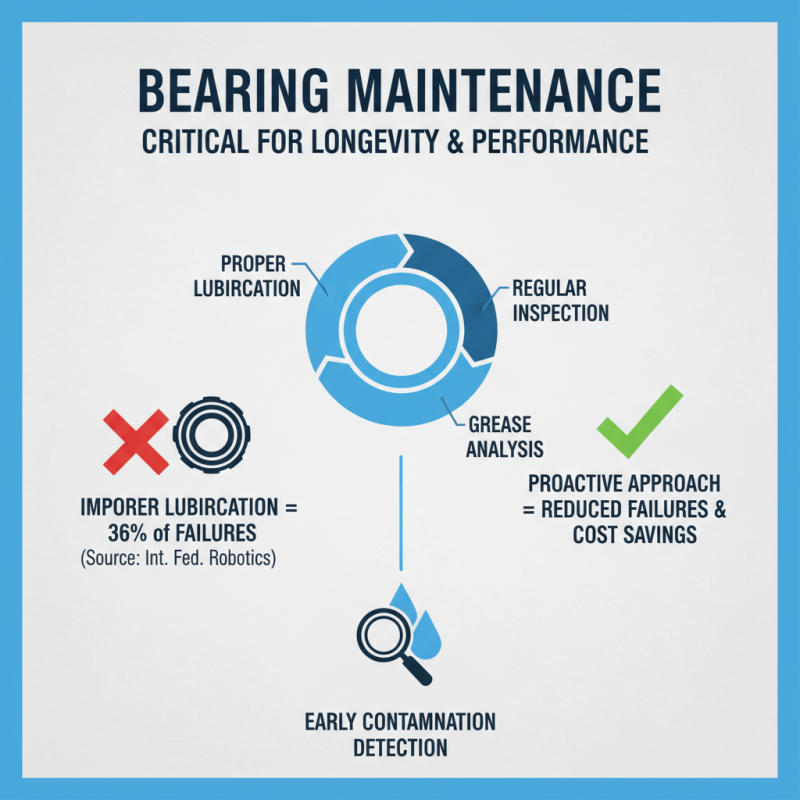

Proper maintenance of bearings is critical to ensure their longevity and optimal performance. According to a report from the International Federation of Robotics, improper lubrication is responsible for 36% of bearing failures. Regular inspection and maintenance can dramatically reduce these failures. A simple grease analysis can identify contamination issues early. This proactive approach saves companies considerable downtime and repair costs.

Another significant factor is operating temperature. Bearings typically have a temperature rating that should not be exceeded. Exceeding this limit can push the lifespan down by as much as 50%, as highlighted in a paper by the Tribological Society. Implementing consistent thermal monitoring could prevent overheating. Furthermore, many engineers forget about vibration analysis. It can reveal alignment issues or imbalance, both of which degrade performance.

Additionally, the environment plays a substantial role. Dust and moisture can infiltrate bearing systems, leading to corrosion. Regular cleaning and sealing of bearing housings can mitigate these risks. Yet, many facilities lack a strict cleaning schedule. This oversight can lead to avoidable failures and increased operational costs. Thoughtful refinements in maintenance practices lead to powerful improvements in bearing life and functionality.

Related Posts

-

How to Choose the Right Real Bearing for Your Needs?

-

The 5 Best Abs Bearings for Ultimate Performance and Durability in 2023

-

How to Choose the Perfect Real Bearing for Your Industrial Applications

-

What is a Car Bearing and How Does it Impact Vehicle Performance

-

Understanding Deep Bearing: Types, Applications, and Benefits Explained

-

10 Facts About Real Bearing for Optimal Performance in Your Machinery