10 Best Truck Bearings for Optimal Performance in 2026?

As the trucking industry evolves, the importance of high-quality truck bearings cannot be overstated. According to a recent report by the Bearing Manufacturers Association, the global bearing market is projected to reach $100 billion by 2026. Truck bearings play a crucial role in enhancing vehicle performance and fuel efficiency. They are vital in reducing friction, ensuring smooth operation under heavy loads.

In 2026, the demand for durable and effective truck bearings will grow. The rise in e-commerce and logistics necessitates reliable equipment. However, not all truck bearings meet the industry standards. Some may lack robustness, leading to premature wear and costly repairs. Choosing the right bearings requires careful consideration of material quality and design.

Investing in top truck bearings could prevent long-term issues. Companies should be aware of their options and the potential pitfalls of subpar products. Understanding the specific needs of your truck and its applications is essential. Ultimately, making informed choices leads to better performance and efficiency on the road.

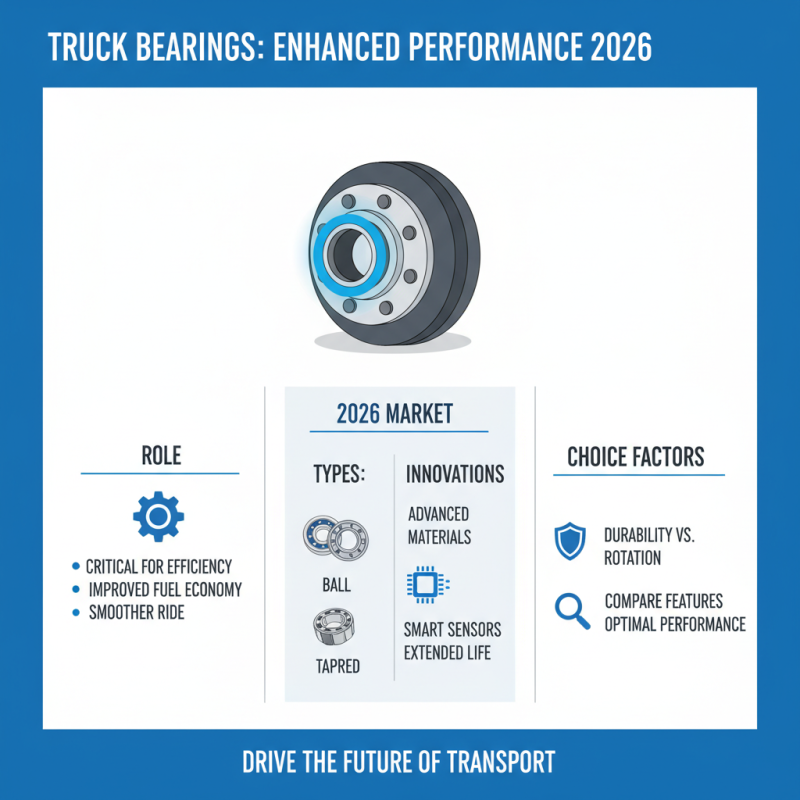

Overview of Truck Bearings and Their Importance in Performance

Truck bearings are essential components that contribute significantly to a vehicle's overall performance. They reduce friction between moving parts and support various loads in the truck's systems. Properly functioning bearings ensure a smooth ride, improved fuel efficiency, and increased lifespan of other vehicle components. Neglected bearings can lead to major performance issues, affecting not only efficiency but also safety.

Common failure signs include unusual noises, overheating, and vibrations. Ignoring these signs might result in costly repairs. It’s easy to overlook these small but vital parts during maintenance. Many drivers focus on more visible issues like tires or brakes. However, the importance of truck bearings cannot be understated. Regular inspection and timely replacement can prevent unexpected breakdowns.

Different environments affect bearing performance too. Dusty roads and heavy loads demand high-quality materials for optimal durability. Choosing the right bearings involves careful consideration of your truck's specific needs. This is an area that deserves more attention from truck owners. Performance can only be maximized by acknowledging these intricacies.

10 Best Truck Bearings for Optimal Performance in 2026

This bar chart illustrates the performance metrics of truck bearings in 2026. Key factors such as durability, load capacity, friction coefficient, temperature resistance, and maintenance frequency are measured on a scale of 0 to 100, indicating their importance in optimizing truck performance.

Key Features to Consider When Choosing Truck Bearings

When choosing truck bearings for optimal performance in 2026, several key features matter. First, consider the material. High-quality steel or ceramic options can significantly enhance durability. They resist wear and tear better under heavy loads. This is crucial for trucks that operate in harsh conditions. Also, pay attention to the seal type. Sealed or shielded bearings can prevent dirt and moisture from entering. This keeps the grease intact, prolonging bearing life.

Another important feature is the bearing's load rating. It indicates how much weight it can support. Ensure that the specifications match your truck's requirements. Additionally, look for noise levels. Some bearings operate more quietly than others. This can make a noticeable difference, especially on long hauls. Keep in mind the maintenance of the bearings. Some require more frequent lubrication than others. Understanding this can save you time and money.

Lastly, don't overlook compatibility. Ensure the bearings fit your truck model. Mismatched sizes can lead to premature failure. It's essential to invest time in researching options. Analyze reviews and user feedback to find the right fit. Overlooking these elements could lead to operational issues. Regular checks and balanced choices will enhance your truck's performance.

Top 10 Truck Bearings for Enhanced Durability and Efficiency

Truck bearings play a crucial role in enhancing durability and efficiency. High-quality bearings ensure smooth operations and reduce friction. According to a recent industry report, nearly 70% of bearing failures stem from inadequate lubrication and improper installation. This highlights the need for thoughtful selection and maintenance.

In 2026, the demand for advanced materials such as ceramics and composites is expected to rise. These materials offer improved resistance to wear and corrosion. A study indicated that ceramic bearings have a lifespan up to three times longer than standard steel bearings under similar conditions. While these innovations provide benefits, they come with higher initial costs and require specialized handling.

Selecting the right bearing is not just about longevity. It involves considering load ratings and environmental conditions. Many users overlook proper fit and installation methods. An improperly installed bearing can lead to catastrophic failures. If adjustments are not routinely made, performance can decline quickly. Awareness of these factors is essential for optimal truck performance.

Comparative Analysis of Truck Bearing Brands in 2026

Truck bearings play a vital role in performance. An optimal bearing can enhance a truck’s efficiency. In 2026, the market offers a variety of options. It’s important to compare the features and performance of different types. Some bearings excel in durability, while others may offer smoother rotations.

When evaluating brands, consider the materials used. Higher-grade steel can result in longer-lasting bearings. Lubrication also matters. Some designs allow for easier maintenance, making them more user-friendly. Testing these bearings in real-world conditions is essential. For example, in extreme climates, certain bearings may underperform.

Choosing the right bearing isn't straightforward. Factors like load capacity and speed ratings are critical. Costs can vary widely, making it a challenge to find the perfect balance. Users often report frustrations with replacements. Inconsistent quality across brands means careful research is needed. Just because a bearing is popular doesn’t guarantee it will meet individual needs.

Maintenance Tips for Maximizing Truck Bearing Lifespan and Functionality

Truck bearings play a crucial role in ensuring smooth operation. Proper maintenance is essential for longevity and performance. Regular checks can prevent unexpected breakdowns and costly repairs. To maximize the lifespan of truck bearings, consider these tips.

Cleanliness is vital. Dirt and grime can degrade bearings quickly. Regularly inspect the bearings for any visible contaminants. If you notice build-up, clean them carefully with appropriate solvents. Be gentle to avoid damaging the seals. Always ensure that lubricants are fresh and suitable for your truck's needs.

Pay attention to load and usage. Overloading can stress bearings and lead to early failure. Know your vehicle's limits. Driving on rough terrain can also affect bearing performance. If you frequently navigate tough roads, more frequent inspections may be needed. Riding smoothly might seem tedious, but it pays off in the long run.

10 Best Truck Bearings for Optimal Performance in 2026

| Bearing Type | Load Rating (kg) | Material | Operating Temperature (°C) | Lifespan (hours) | Maintenance Tips |

|---|---|---|---|---|---|

| Ball Bearing | 1500 | Steel | -20 to 120 | 8000 | Regular lubrication every 6 months |

| Roller Bearing | 2000 | Carbon Steel | -20 to 130 | 6000 | Inspect seal integrity regularly |

| Tapered Bearing | 1800 | Chrome Steel | -30 to 150 | 7000 | Keep them dry and well-greased |

| Spherical Bearing | 1600 | Stainless Steel | -10 to 140 | 6500 | Check for corrosion and clean accordingly |

| Needle Bearing | 1400 | Alloy Steel | -20 to 100 | 7000 | Minimal lubrication is required, but frequent checks are essential |

Related Posts

-

Top Tips for Choosing Truck Bearings to Enhance Performance and Longevity

-

10 Best Truck Bearings for Optimal Performance and Durability

-

How to Choose the Right Tyre Bearing for Your Vehicle Needs

-

Top 5 Benefits of Using High Quality Brake Bearings in Automotive Applications

-

The Ultimate Guide to Choosing the Best Bearing Needles in 2025

-

Unlocking Efficiency: The Essential Guide to Choosing the Right Auto Bearing for Your Vehicle