2026 How to Choose the Right Power Bearings for Optimal Performance?

Choosing the right Power Bearings is crucial for any machinery. An optimal selection can enhance performance, reduce downtime, and improve efficiency. According to a recent report by Global Market Insights, the demand for Power Bearings is expected to grow at a rate of 5.5% annually through 2026. This growth highlights the importance of understanding how to choose the right bearings for specific applications.

Dr. Emily Carter, a leading expert in the Power Bearings industry, states, “Choosing the right Power Bearings can significantly influence a machine's overall reliability.” Many industries still struggle with improper bearing selection, leading to costly failures. Each application demands unique specifications, yet many overlook critical factors like load capacity and operating conditions.

Failing to consider these aspects can result in performance issues and increased maintenance. Manufacturers often rush decisions or rely on outdated information. This leads to a cycle of inefficiency. Evaluating your options carefully can make all the difference for machinery longevity and productivity.

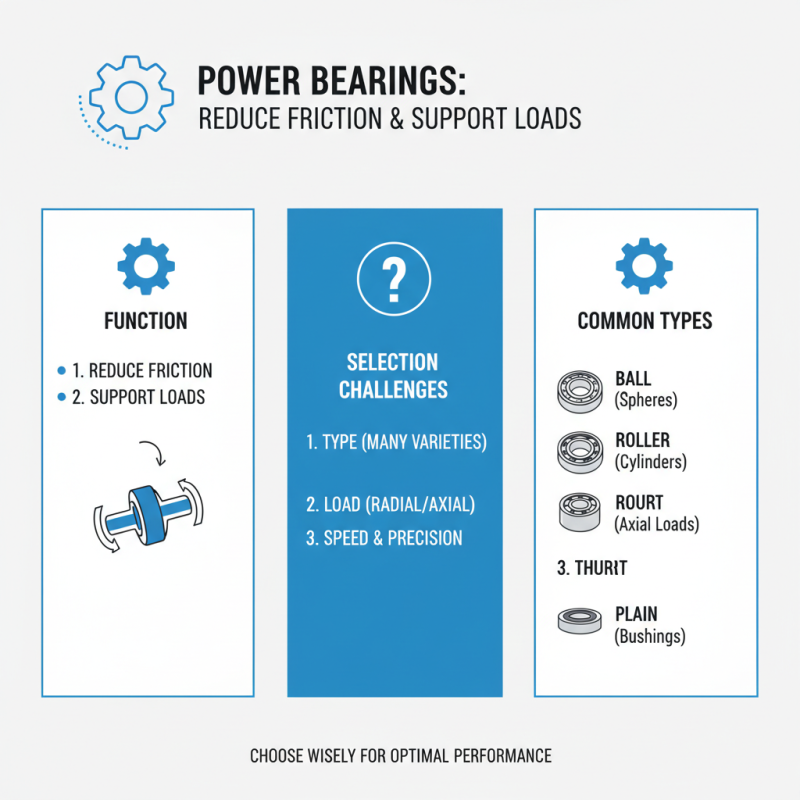

Understanding Power Bearings: An Overview of Types and Applications

Power bearings are essential for many mechanical applications. They help reduce friction and support loads. Selecting the right type can be challenging. There are various types of power bearings, each serving a different function.

Ball bearings are common and versatile. They provide smooth motion and can handle radial and axial loads. Roller bearings, on the other hand, excel in heavy load situations. They often offer better load distribution. Thrust bearings allow for support against axial loads. Each type has unique strengths and weaknesses.

Understanding the specific requirements of your application is crucial. Consider factors like load type, speed, and environmental conditions. Sometimes, a bearing may not perform as expected. This can lead to frequent replacements or maintenance. Not every choice will be perfect, and reflection is important. Evaluating your options thoroughly will lead to better performance.

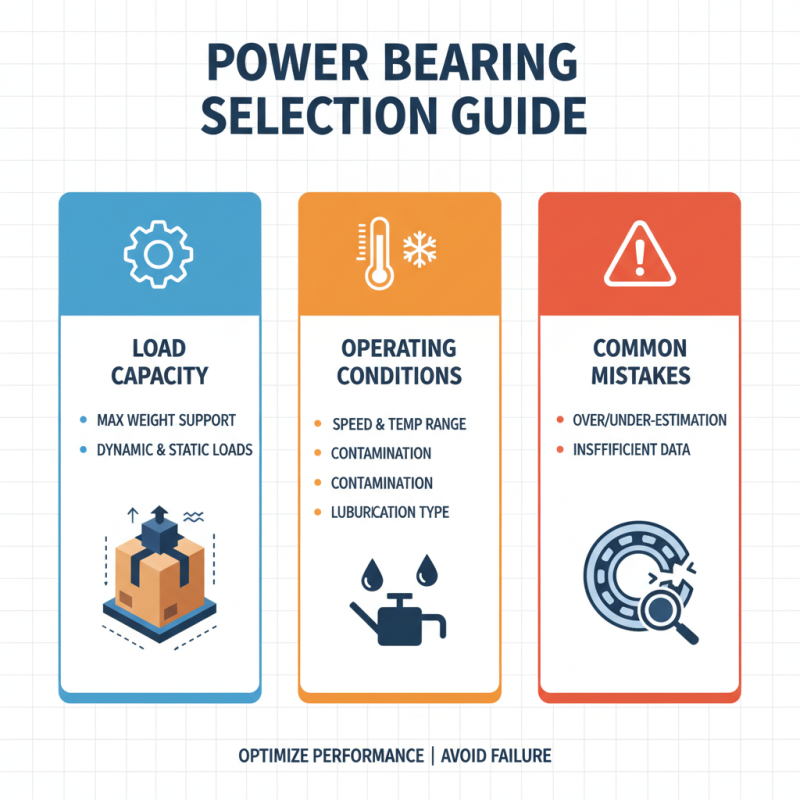

Identifying Key Performance Factors in Power Bearings Selection

Choosing the right power bearings is crucial for optimal performance. It involves understanding key performance factors. Load capacity, speed rating, and environmental conditions play significant roles. Each bearing type responds differently under varying conditions. This can lead to unexpected outcomes if not carefully considered.

One critical factor is load capacity. It affects durability and efficiency. A bearing that is over or under-loaded can fail quickly. Similarly, speed rating is vital. Bearings must handle the operational speeds without overheating. Many overlook the temperature ranges that bearings face. Extreme conditions can drastically affect performance and lifespan.

Environmental conditions matter too. Dust, moisture, and chemicals can degrade bearings over time. Some might think all bearings can handle harsh environments. This is a misconception that can result in costly downtime. Regular maintenance and proper lubrication are often neglected. These practices can greatly influence bearing performance. Reflecting on these aspects ensures more reliable operations.

Performance Factors in Power Bearings Selection

Assessing Load Capacity and Operating Conditions for Optimal Choices

Choosing power bearings involves understanding load capacity and operating conditions. Load capacity determines how much weight the bearing can support under different circumstances. It's essential to accurately assess the expected loads. Overestimating or underestimating load can lead to performance issues. This mistake often arises from insufficient data or assumptions based on past experiences.

Operating conditions are also crucial. Factors like temperature, moisture, and speed play significant roles. A bearing may perform well in one environment but fail in another. For instance, high temperatures can reduce lubrication effectiveness. Understanding these variables can prevent unpleasant surprises.

**Tips:** Always gather data on the specific application. Regularly check operating conditions. Don’t hesitate to consult experts if unsure. It is better to be cautious than to face unexpected failures. Analyze past performance and learn from failures. Adjust specifications as needed. A small oversight can lead to costly downtime.

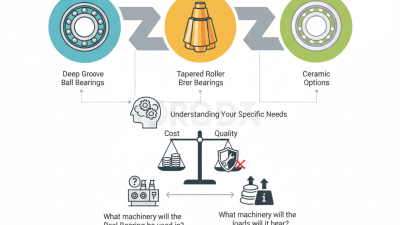

Evaluating Material Composition and Durability in Power Bearings

When selecting power bearings, material composition is crucial. Different materials offer varying levels of strength, weight, and resistance to wear. For example, steel bearings are sturdy but may rust. On the other hand, ceramic bearings are lighter and often more durable. However, they can be brittle.

Tips: Think about the environment in which the bearings will operate. High temperatures or corrosive substances can influence the material choice significantly.

Durability is another important aspect. A bearing may perform well at first, but its lifespan needs to be considered. Regular maintenance plays a role here. Check for signs of wear, like unusual noises or vibrations. Sometimes, replacing a component can prevent more significant issues later.

Tips: Regular inspections can save time and money. Look for cracks or discoloration on bearings during routine checks.

Understanding your specific application aids in choosing the right bearings. If they do not meet the required standards, performance can drop. It's essential to match the bearing's characteristics with the intended use. This can be a trial-and-error process, but careful evaluation can lead to better outcomes.

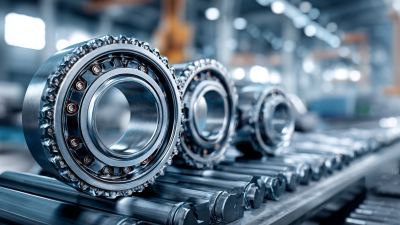

Best Practices for Maintenance and Replacement of Power Bearings

Power bearings play a crucial role in various machinery applications. Their performance directly impacts efficiency and longevity. To ensure optimal function, regular maintenance is vital. Inspections should be done frequently. Check for signs of wear or damage. If you notice unusual noises, take action immediately.

Proper lubrication is essential. It minimizes friction and prolongs bearing life. Use the right type and amount of lubricant. Too much grease can create pressure and lead to failure. Conversely, too little can cause overheating. Balance is key here. Keep an eye on operating temperatures to help gauge performance.

Timely replacement is equally important. Plan for periodic checks, especially in high-demand environments. A worn bearing can cause breakdowns. Identify when it’s time for a change to avoid unexpected downtimes. Reflect on your maintenance practices regularly. Are they effective? Adjust them based on performance results.

| Bearing Type | Load Capacity (kg) | Speed Rating (RPM) | Material | Maintenance Interval (Hours) | Replacement Frequency (Years) |

|---|---|---|---|---|---|

| Ball Bearing | 1000 | 12000 | Steel | 500 | 5 |

| Roller Bearing | 1500 | 8000 | Chrome Steel | 600 | 7 |

| Angular Contact Bearing | 1200 | 10000 | Ceramic | 400 | 6 |

| Self-Aligning Bearing | 2000 | 6000 | Stainless Steel | 300 | 4 |

| Thrust Bearing | 1800 | 7000 | Carbon Steel | 250 | 3 |

Related Posts

-

Exploring Opportunities for Auto Bearings at the 138th Canton Fair 2025: Industry Trends and Insights

-

What is a Car Bearing and How Does it Impact Vehicle Performance

-

Best Real Bearing Types for Your Needs?

-

How to Choose the Perfect Real Bearing for Your Industrial Applications

-

How to Choose the Right Tyre Bearing for Your Vehicle Needs

-

How to Choose the Right Tape Bearing for Your Project Needs